Hot Dip Galvanizing, or HDG as it’s sometimes referred to, is a process of immersing ferrous iron articles into 450 degrees celsius molten zinc. The base steel & zinc metallurgically reacts to form three layers of zinc iron-alloy layers and one zinc pure layer. It’s one of the smarter choices of protecting steel from corrosion, and providing a tough, abrasion resistant coating that will last for many years to come in the right environment.

Why does the hot dip galvanized finish look different on the same piece of steel?

There are a number of reasons why galvanized finished appearances may look different on the same piece of steel, and this all relates to steel chemistry during the manufacturing process. Phosphorous & Silicon are two of the main contributors in finished appearances, where the steel becomes reactive with the zinc resulting in thicker coatings, uneven surfaces (striations) or delamination in extreme cases leading to dull coatings rather than bright shiny finishes.

What is Wet Storage Stain or White rust?

Wet Storage Stain, also commonly known as White Rust, is a light powder deposit which forms on newly galvanized products. This phenomenon occurs when products are packed too tightly with poor ventilation, or when rainwater, moisture or condensation is present and is attacking the outer pure zinc layer.

How do I prevent White Rust from occurring?

White rust can be prevented by storing freshly galvanized product off the ground in a well ventilated area. Tightly packed product should be avoided or separated to allow for adequate venting and free flowing air. Product of similar shapes and sizes should be placed on an angle to allow for water to run off and not pool on the object.

How do I repair White Rust?

White rust can be treated with a stiff nylon bristle brush and a mild metal cleaning solution applied in a circular motion. Products such as CLR or a DIY solution of a slightly acidic mix of water and vinegar and a little dishwashing liquid can also be used to address this issue. Once cleaned the product should be rinsed off with running water and allowed to dry.

What sizes are the baths at Hunter Galvanizing?

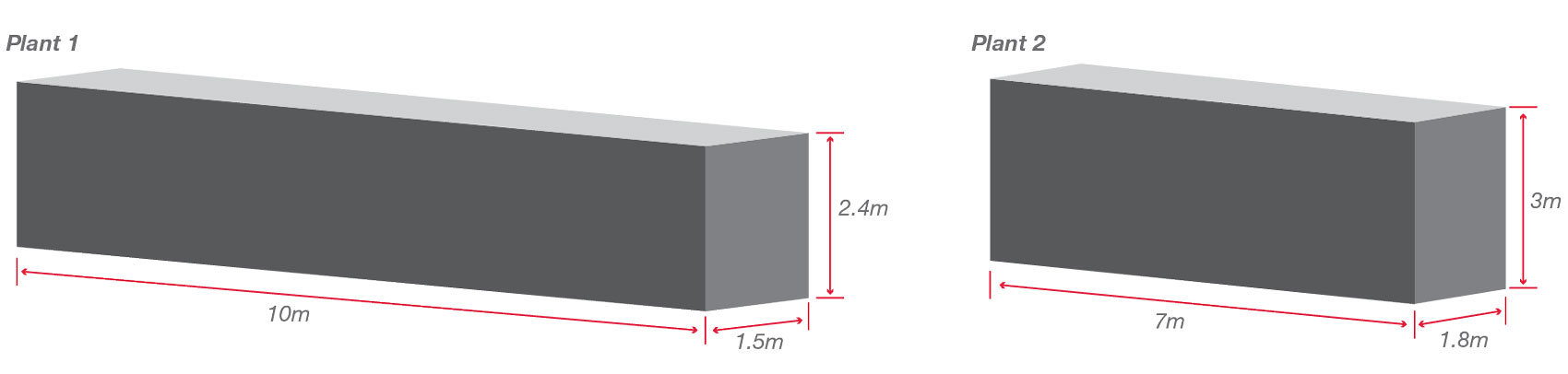

Hunter Galvanizing has two Hot Dip Galvanizing baths at our Tomago facility.

Our bath sizes below are the physical dimension only, therefore all fabricated articles should have at least a 100mm clearance in Length, Width & Depth to allow the job to be galvanized as a single dip successfully. All articles greater than our kettle sizes, also known as a double dip must be discussed with one of our sales team staff.

Plant 1: 10m(L) x 1.5m(W) x 2.4m(D)

Plant 2: 7m(L) x 1.7m(W) x 3m(D)

What is ``Double Dipping``?

Double dipping is a term related to partially dipping an article greater in size than the bath dimensions can accommodate, this can either be in length or width. On removal from the bath, the article is flipped and the remaining uncoated area is submerged back in the molten zinc, ensuring coverage of the entire surface has been achieved. The term double dipping has no bearing on the coating thickness.

How do I calculate my galvanizing cost?

All Hot Dip Galvanizing is based on the final weight of your HDG Steel. This is calculated by adding up to an additional 10% on top of the weight of your uncoated material in kg’s and multiplying by the galvanizing rate in $per Tonnes. Contact our sales team on (02) 4964 9555 for a quote.

Do you offer Warranties?

Hunter Galvanizing warrants the hot dip galvanized coating thickness on the steelwork processed is adequate to withstand the accepted corrosion rate for a number of years dependant on the location of the end use from the date of application. Click here for further information regarding life expectancy and Time to First Maintenance of Hot Dip Galvanized products.

At the time of application, Hunter Galvanizing warrants the hot dip galvanized coating meets the current relevant Australian Standards. Please contact the team for more information regarding the Warranty of your Hot Dip Galvanized product/s.